convert automatic car to manual

Converting an automatic car to manual involves swapping the transmission, pedals, and linkage, requiring mechanical expertise and significant investment. It’s a complex process, not for beginners.

Why Convert an Automatic Car to Manual?

Converting an automatic car to manual offers several benefits, including enhanced driving control, improved fuel efficiency, and a more engaging driving experience. Many enthusiasts prefer manual transmissions for their precision and connection to the vehicle. Additionally, manual transmissions are often lighter and more cost-effective in the long run. For classic or tuner cars, such as Honda Civics or Ford Mustangs, a manual swap can enhance performance and value. Some drivers may also convert to manual for specific needs, like rare car models only available in automatic, or to address mobility issues. Overall, the switch is driven by personal preference, performance goals, or practical requirements, making it a popular modification among car enthusiasts.

Overview of the Conversion Process

The conversion from automatic to manual transmission is a multi-step process requiring careful planning and mechanical expertise. It begins with removing the automatic transmission and replacing it with a compatible manual unit. This involves installing a new clutch system, pedals, and linkage. The vehicle’s electrical and wiring systems must also be modified to support manual operation, including updates to the ECU. Additionally, the gear linkage and shifter mechanism need to be properly adjusted for smooth operation. Finally, the vehicle must be thoroughly tested and tuned to ensure optimal performance. This complex process demands precision and often requires professional assistance to avoid costly errors and ensure reliability.

Assessing Feasibility and Requirements

Assessing feasibility involves evaluating the car’s make, model, and compatibility with manual components. Costs, time, and technical expertise are critical factors to consider before proceeding with the conversion.

Vehicle Make and Model Considerations

When converting an automatic car to manual, the vehicle’s make and model play a crucial role. Popular models like Honda Civics, Toyota Corollas, and Ford Mustangs are often chosen due to their factory manual transmission options and strong aftermarket support. Cars with existing manual versions are easier to convert, as components like pedals, linkages, and transmissions are readily available. However, for cars without a factory manual option, the process becomes more complex and costly. Researching the availability of compatible parts and swap kits is essential. For instance, the Toyota Corolla may require a flywheel and clutch from a manual variant, while the Nissan 350Z might need a specific transmission swap. Choosing a model with a proven track record for conversions ensures a smoother process and reduces unexpected challenges.

Cost and Time Implications

Converting an automatic car to manual is a costly and time-consuming process. Parts like a manual transmission, clutch, and pedal assembly can range from $1,000 to $3,000 or more, depending on the vehicle. Labor costs are significant, often between $1,000 and $2,000, especially if a professional is involved. The total investment can easily exceed $5,000. Time-wise, the process may take several days to weeks, depending on complexity. Factors such as rare parts or additional repairs can further increase costs and duration. This substantial financial and time commitment makes it essential to carefully consider the feasibility and value of the conversion.

Technical Expertise and Tools Needed

Converting an automatic car to manual requires advanced mechanical skills and specialized tools. A deep understanding of transmission systems, hydraulics, and electronics is essential. Tools needed include transmission jacks, clutch alignment tools, and welding equipment. Additionally, access to a well-equipped workshop is necessary. Without proper expertise, the process can lead to costly mistakes, making professional assistance often unavoidable for novices. The complexity of modern vehicles further amplifies the need for precision and knowledge, ensuring the conversion is done safely and effectively. This underscores the importance of evaluating one’s technical capabilities before embarking on such a project.

Key Components for Conversion

The process requires replacing the automatic transmission with a manual one, installing a clutch pedal and linkage, and modifying the ECU and wiring system accordingly.

Transmission Replacement

Replacing the automatic transmission with a manual one is the core of the conversion process. This involves selecting a compatible manual transmission that fits the car’s make and model. Compatibility with the engine, driveshaft, and chassis must be ensured. The transmission swap requires removing the automatic unit and installing the manual gearbox, which may involve modifying mounts and crossmembers. Specialized tools and mechanical expertise are essential for this step. While challenging, the transmission replacement is a critical milestone in achieving a manual drivetrain, offering better control and driving experience. Proper alignment and connection to the clutch system are vital for smooth operation. This step demands careful planning and execution to ensure reliability and performance.

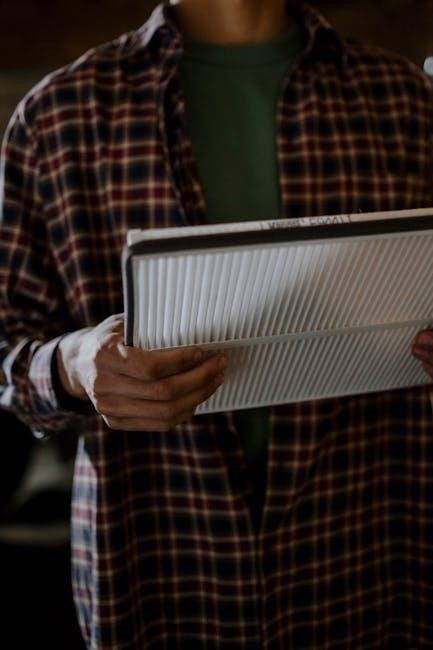

Clutch Pedal and Linkage Installation

Installing a clutch pedal and linkage is essential for manual transmission functionality. This involves removing the automatic shifter and center console to fit the new pedal assembly. The clutch pedal connects to the master cylinder, which engages the clutch via hydraulic or mechanical linkage. Proper alignment and adjustment of the linkage ensure smooth gear shifts. This step requires careful installation to avoid misalignment, which could lead to poor shifting performance or clutch failure. The clutch system must be synchronized with the manual transmission for optimal operation. Professional expertise is often recommended to ensure precision and reliability in this critical component of the conversion process.

ECU and Wiring Modifications

Modifying the ECU and wiring is crucial when converting an automatic car to manual. The ECU must be reprogrammed or replaced to recognize the manual transmission, as it relies on specific sensors and software. Automatic transmissions use a torque converter and different gear sensors, which must be deactivated or removed. Additional sensors and wiring for the manual transmission, such as clutch and gear position sensors, may need to be installed. This ensures proper communication between the ECU and the new manual components. Incorrect modifications can lead to poor performance or electrical issues, making it essential to consult a specialist for accurate configurations. Proper ECU calibration ensures smooth operation of the manual transmission, optimizing both performance and drivability.

Step-by-Step Conversion Process

Converting an automatic car to manual involves removing the automatic transmission, installing a manual transmission, integrating the clutch system, and adjusting the gear linkage for proper operation.

Removing the Automatic Transmission

Removing the automatic transmission is the first major step in the conversion process. It involves disconnecting the transmission from the engine and other components. Start by draining the transmission fluid and disconnecting the coolant lines, electrical connectors, and shift linkage. Next, remove the transmission mounts and any additional brackets or supports. Carefully lift the transmission out of the car using a jack or hoist, ensuring not to damage surrounding components. Proper tools and a clean workspace are essential to avoid complications. This step requires precision and mechanical knowledge to prevent any damage to the vehicle. Safety precautions should be taken to handle the heavy transmission securely.

Installing the Manual Transmission

Installing the manual transmission requires precise alignment with the engine. Begin by positioning the manual transmission and ensuring the input shaft aligns with the clutch. Secure the transmission using the appropriate mounts and bolts, following the manufacturer’s torque specifications. Reconnect the driveshaft, clutch linkage, and any electrical connectors. Ensure all components are properly aligned to avoid damage. Test the gearshift operation to confirm smooth engagement. This step demands attention to detail and mechanical aptitude to ensure proper function. Once installed, double-check all connections and perform a test run to verify the transmission operates correctly.

Integrating the Clutch System

Integrating the clutch system is crucial for manual transmission functionality. Begin by installing the clutch pedal assembly, ensuring it connects smoothly to the clutch master cylinder. The clutch master cylinder must align with the clutch slave cylinder to facilitate proper hydraulic engagement. Install the flywheel and clutch disc, ensuring they are securely fastened to the engine. Connect the hydraulic or cable-actuated linkage, adjusting the clutch pedal’s free play as specified. Bleed the hydraulic system to eliminate air bubbles, ensuring smooth clutch operation. Test the system by engaging gears to confirm proper clutch engagement and disengagement. This step ensures the driver can control the vehicle seamlessly, making it essential for a successful conversion.

Adjusting the Gear Linkage

Adjusting the gear linkage is essential for precise gear engagement. Begin by removing the center console and auto-shift shroud to access the linkage. Install the manual gear linkage, ensuring proper alignment with the transmission. Use wrenches and screwdrivers to secure the linkage and adjust its length. Fine-tune the gear lever’s position to match the driver’s preference. Test each gear to confirm smooth shifting and proper engagement. Ensure minimal play in the gear lever for precise control. This step ensures the driver can seamlessly transition between gears, enhancing the overall driving experience. Proper adjustment is critical for avoiding misalignment and ensuring reliable transmission performance.

Post-Conversion Considerations

After converting, test the vehicle thoroughly to ensure smooth operation. Check legal requirements and obtain necessary approvals. Regular maintenance is crucial for long-term performance and reliability.

Tuning and Testing the Vehicle

Tuning and testing are critical after converting an automatic car to manual. Ensure the clutch engages smoothly and gears shift seamlessly. Check for proper transmission mounting and linkage alignment. A professional mechanic may fine-tune the ECU for optimal performance, especially in modern vehicles with advanced systems. Test drive the car on various terrains to identify any issues. Pay attention to unusual noises or vibrations, which could indicate improper installation. Regular maintenance, such as fluid checks and clutch adjustments, is essential for long-term reliability. Consider upgrading to a transmission with overdrive for improved highway performance. Skipping these steps can lead to poor drivability or even system failure; Always prioritize thorough testing to ensure a safe and enjoyable driving experience.

Legal and Licensing Requirements

After converting an automatic car to manual, ensure compliance with local legal requirements. Many jurisdictions mandate inspections for modified vehicles to verify safety and emissions standards. Additionally, check if your driver’s license permits operating a manual transmission vehicle. In some regions, a manual endorsement is required, which may involve passing a driving test. Failure to comply could result in fines or legal penalties. Research your area’s specific regulations regarding transmission conversions. Proper documentation and certification may also be needed to register the vehicle legally. Always verify with local authorities to avoid issues and ensure your conversion meets all necessary standards and legal obligations.

Maintenance Tips for Manual Transmission

Regular maintenance is crucial for a manual transmission to ensure smooth operation and longevity. Check the transmission fluid level periodically, as low fluid can lead to overheating and wear. Replace the fluid every 30,000 to 60,000 miles, depending on the manufacturer’s recommendations. Inspect the clutch for wear and adjust it as needed to maintain proper engagement. Lubricate the shift linkage and clutch pedal regularly to prevent stiffness. Monitor for unusual noises or vibrations, as these could indicate issues with gears or bearings. Address any problems promptly to avoid costly repairs. Keep the transmission clean and free from debris. Following these tips will help maintain your manual transmission’s performance and extend its lifespan.

Converting an automatic car to manual is a challenging yet rewarding endeavor, offering enhanced driving control and engagement. While the process demands significant time, money, and mechanical expertise, the end result can be deeply satisfying for enthusiasts. Proper planning, research, and execution are essential to ensure success. For those with the passion and resources, this conversion can breathe new life into a vehicle, making it more aligned with their driving preferences. However, it’s crucial to weigh the costs and complexities against the benefits before embarking on this project. Ultimately, a successful conversion not only improves performance but also fosters a deeper connection between the driver and the car.